Manganese Alloy

Nature of operations

Constructed in 1957, smelting operations began in 1959 and metal-recovery plant was commissioned in 2005

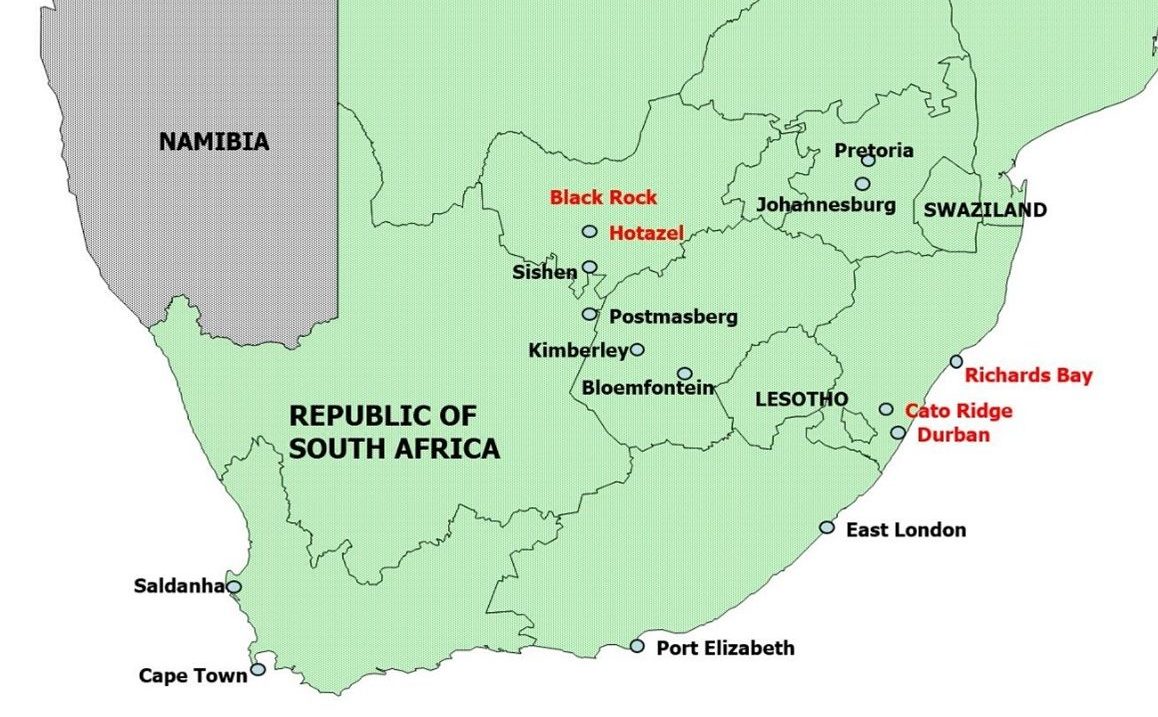

Location: Cato Ridge, KwaZulu-Natal, South Africa

High and medium-carbon and/or low-carbon ferromanganese smelting operation (including raw materials, smelting, crushing, screening, metal-recovery processes)

Number of employees

Permanent employees – 358

Contractors – 193

Cato Ridge Works

To beneficiate manganese ore from our mines in the Northern Cape, we established Cato Ridge Works (formerly Feralloys Limited) in 1956 and constructed a ferromanganese smelter at Cato Ridge, some 60km from Durban in KwaZulu-Natal. The first alloy from this plant was exported in 1959.

Assmang is among the top ten producers of ferromanganese globally.

Cato Ridge Works currently operates three submerged arc furnaces, controlled by programmable logic controller or PLC-based supervisory systems. In addition, we operate a metal-recovery plant from slag, with current hot-metal capacity of around 140 000 tonnes per annum. Some 60% of this product is sold to Cato Ridge Alloys to be converted to refined alloy and most of the balance is sold as high-carbon alloy in the export market.

Cato Ridge Alloys

Cato Ridge Alloys is a joint venture established in 1997 between Assmang, Mizushima Ferroalloy Company Ltd and Sumitomo Corporation. It produces refined medium and/or low-carbon ferromanganese products.

Cato Ridge Alloys (CRA) is a joint venture established in 1997 between Assmang, Mizushima Ferroalloy Co. Ltd and Sumitomo Corporation. CRA produces refined medium- and low-carbon ferromanganese products.