1867

Geological exploration starts in the Northern Cape province of South Africa.

1876

Surveys on farms Beeshoek, Doornfontein, Driehoekspan and Paling

1907

Manganese identified at Black Rock. The immense potential of South Africa’s manganese deposits is finally understood, but the lack of a rail link deters investment

1926

Captain Thomas Shone and his partners set up Union Manganese Mines and Minerals Limited. They buy seven properties, including Bruce and King, and obtain mineral leases for others, such as Beeshoek and Bishop

1928

Guido Sacco forms Gloucester Manganese and Manganese Corporation near Postmasburg, Northern Cape (near Beeshoek). His son, Desmond, becomes chairman of Assmang in 1999

1929

Thomas Shone registers Manganese Corporation Limited, and large-scale production begins at its Beeshoek property

1930

Koopmansfontein-Postmasburg railway line is opened for freight business

1934

Anglo Transvaal Consolidated Investment Company Limited (Anglovaal) is established by Bob Hersov and Slip Menell. Guido Sacco approaches Bob Hersov to restructure the industry and forms African Mining and Trust

1935

Anglovaal and African Mining and Trust, as partners, register a new company to mine the Gloucester deposits (see 1928). It is named Associated Manganese Mines of South Africa Limited (Ammosal), now Assmang Proprietary Limited

1936

First manganese ore from Ammosal exported from Durban

1940

Assmang acquires Black Rock, Northern Cape, and opens a new mine

1945

Black Rock Mine is closed by a shortage of railway trucks to the Gloucester railhead as well as shipping capacity

1948

After WWII, several mines, including Black Rock, reopen to fuel reconstruction in Europe

1950

Second rush for ore-bearing properties. Assmang has options in the Kalahari on Nchwaning, Belgravia, Santoy and Gloria. It obtains titles to vast deposits of manganese ore that will last for decades (today, the Kalahari basin is considered the largest and richest manganese deposit in the world)

1956

Negotiations between Anglovaal and African Mining and Trust result in acquiring the entire share capital of Gloucester Manganese, which becomes Assmang’s first wholly owned subsidiary. Gloucester, Bishop and Paling mines continue to operate, producing low-grade ore but, by the end of the 1960s, some of the mines are closed

1959

Faced with ongoing rail-capacity challenges, Assmang diversifies into mineral beneficiation. Its second wholly owned subsidiary, Ferralloys Limited, produces ferromanganese and pig iron. Assmang opens two open-pit mines – Devon and Adams – to supply Ferralloys’ furnaces with manganese ore

1961

Rail extension from Sishen to Hotazel, Northern Cape, completed

1962

Eskom power reaches Beeshoek and Gloucester. Old and primitive mining methods give way to industrial machinery

1964

First iron ore exported

1967

At least 120 railway trucks dispatched daily and iron ore railings exceed 1 million tonnes

1969

Assmang diversifies into low-carbon ferrochrome. African Mining and Trust’s consulting engineer recommends that the new plant be located at Fairview, near Machadodorp in Mpumalanga

1970

Assmang becomes the biggest exporter of iron ore in South Africa. Belgravia mine, near Black Rock, opens as a new source of medium and high-grade ore in response to strong increase in global demand

1970

US Steel buys shares in Assmang and agrees to buy iron ore for at least 15 years. Beeshoek is fully upgraded and scattered quarries are consolidated into open-cast pits

1971

Ferrochrome smelter is completed

1975

Black Rock and Belgravia are upgraded. Two new manganese mines at Nchwaning and Gloria are commissioned. Assmang’s capacity has almost doubled and mechanisation is the norm throughout its portfolio

1975

Beeshoek iron ore facilities are enlarged; including commissioning a full washing and screening plant and a jig plant

1980

Assmang reaches agreement with Iscor Ltd, owner of Sishen Iron Ore Mine, to cooperate on mining and railing to the port of Saldanha. Nchwaning 2 is commissioned, with capacity exceeding 3 million tonnes per annum

1981

Railings increase to 1.1 million tonnes, but production forced to stop due to recession and the political aftermath of the Soweto uprisings against apartheid

1982-83

Severe recession in the steel industry stops production at Black Rock, Belgravia and Gloria. Assmang moves into a maintenance and exploration phase. A solid double layer of manganese seams is outlined at Nchwaning, running beneath the Black Rock and Belgravia deposits

1988

Assmang’s performance improves, with both iron ore and manganese ore railings rising to 1.5 million tonnes

1994

Assmang obtains ISO 9002 accreditation – the first southern-hemisphere mining operation to be audited and accredited for all its surface and underground operational functions

1998

Assmang acquires the chrome resource at Dwarsrivier in Mpumalanga, and approves finance to build a mine and expand capacity at Ferralloys in Machadodorp

1998

Cato Ridge Alloys Proprietary Limited is incorporated by Assmang as a new wholly owned subsidiary, and production starts.

1999

Assmang starts planning a new mine on Bruce, King and Mokaning farms (known as BKM and renamed Khumani Mine in 2007). Feasibility study commissioned for a 10-million tonne per year mine

1999

Assmang commissions an extension at Beeshoek Mine (Beeshoek South)

2001

Assmang restructures operations into three divisions: manganese, chrome and iron ore

2001

New jig plant and iron-recovery plant are built, but Beeshoek is reaching the end of its productive life (at the projected production rate of 6 million tonnes of iron ore per year, remaining reserves would be depleted by around 2010. After reconsidering the mine’s reserves, life-of-mine was extended by 15 years to 2022)

2002

New Nchwaning 3 shaft: ventilation shaft completed and 2.2km conveyor decline commissioned

2003

Nchwaning 3 shaft: completed surface infrastructure and underground plant. Commissioned underground production mining

2004

Anglovaal restructures and African Rainbow Minerals (ARM) is formed, becoming the first black economic empowerment (BEE) mining giant in South Africa. N’Chwaning 3 starts production.

2005

Assmang board approves first phase of the BKM project on the Bruce, King and Mokaning properties – to establish an 8.4 million tonne per annum export iron ore mine – following a first commitment from national transport authority, Transnet, to expand the Sishen Orex export rail line

2006

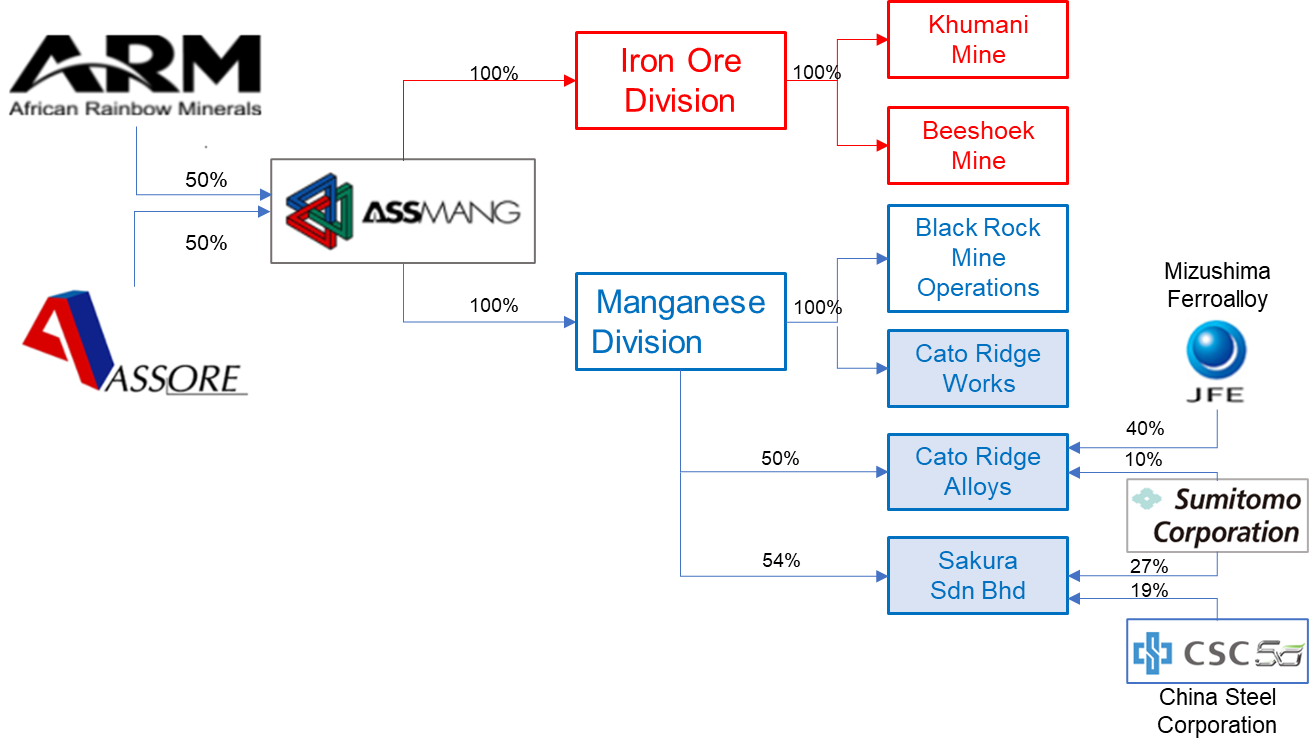

Assore and ARM become the only shareholders of Assmang, each with a 50% interest, and Assmang delists from the JSE. Proceeds are injected into new projects. BKM project: construction starts on the new Khumani Iron Ore Mine

2007

Assmang obtains a mining right for the BKM properties which leads to the birth of Khumani Mine

2008

Khumani: surface plant commissioned and first ore railed to Saldanha export port

2009

Khumani: board approves additional R5.5 billion to expand mine from 10 million tonnes per annum to 14 million tonnes per annum by mining on the King property

2010

Conversion of ferrochrome capacity in Machadodorp to ferromanganese begins

2012

Production of ferrochrome at Machadodorp Works suspended due to adverse conditions in the ferrochrome market. Khumani: King plant commissioned. Khumani ramps up production from 10 million tonnes per annum to 14 million tonnes per annum

2013

Assmang enters into a joint-venture agreement with Sumitomo Corporation and China Steel Corporation to build a manganese alloy smelting facility in the Sarawak state of Malaysia, Sakura Ferroalloys

2014

Black Rock: board approves R7.2 billion capital for sustainable expansion at Nchwaning 3 shaft, Nchwaning 2 shaft, Nchwaning plant infrastructure, and a new ventilation shaft at Gloria

2014

Construction begins at Sakura Ferroalloys plant. Assmang begins Black Rock expansion project to increase manganese output to 4.6 million tonnes per annum by 2020.

2015

Production starts on Village pit at Beeshoek Mine

2016

Commissioned furnace 1 at Sakura Ferroalloys in April, with first sales in May. Furnace 2 commissioned in September

2017

Khumani produces a record 14.7 million tonnes of saleable material .

2017

Nchwaning 2 shaft: completion of surface infrastructure and recommissioning of refurbished Nchwaning 2 vertical men-and-material shaft at Black Rock as part of the renewal and expansion project. This increases installed capacity by 50%. Black Rock Mine commissions new rapid loadout station

2018

Gloria: board approves R2.7 billion for sustainable and renewable capital to modernise surface and underground plant and infrastructure.

2018

Khumani produces record 14.7 million tonnes of saleable material. Surface infrastructure and recommissioning of new shaft completed at Black Rock as part of the expansion project, increasing production by 20%.

2019

Board approves capital expenditure for Black Rock (R7.2 billion) and Gloria R3 billion) projects to modernise and expand the mine’s output by increasing volumes and flexibility to produce various grades of manganese ore at its three operating shafts while improving efficiencies

2020

First 1 million tonnes of high-carbon ferromanganese produced at Sakura Ferroalloys

2021

Assmang exports over 14 million tonnes of iron ore and almost 4 million tonnes of manganese ore. Beeshoek Mine LoM was extended to 15 years.

2021

First 1 million tonnes of high-carbon ferromanganese sales at Sakura Ferroalloys

2022

Sinter plant commissioned at Cato Ridge Works, water-treatment plant commissioned at Sakura Ferroalloys, R10.2 billion expansion projects completed at Black Rock Mine. Black Rock Mine: R7.2 billion sustainable and expansion projects complete. Gloria: R2.7 billion renewal and expansion projects complete.